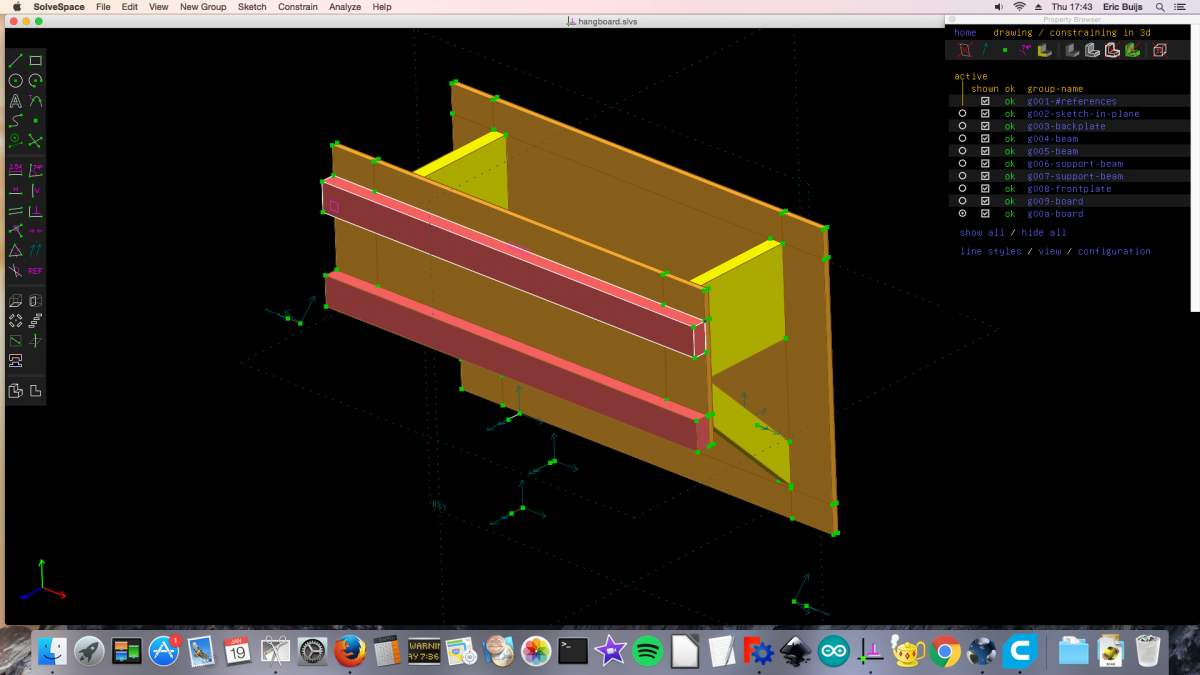

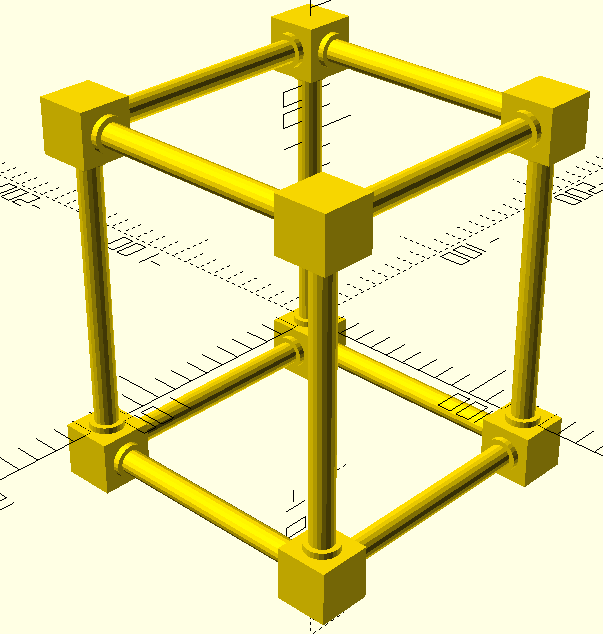

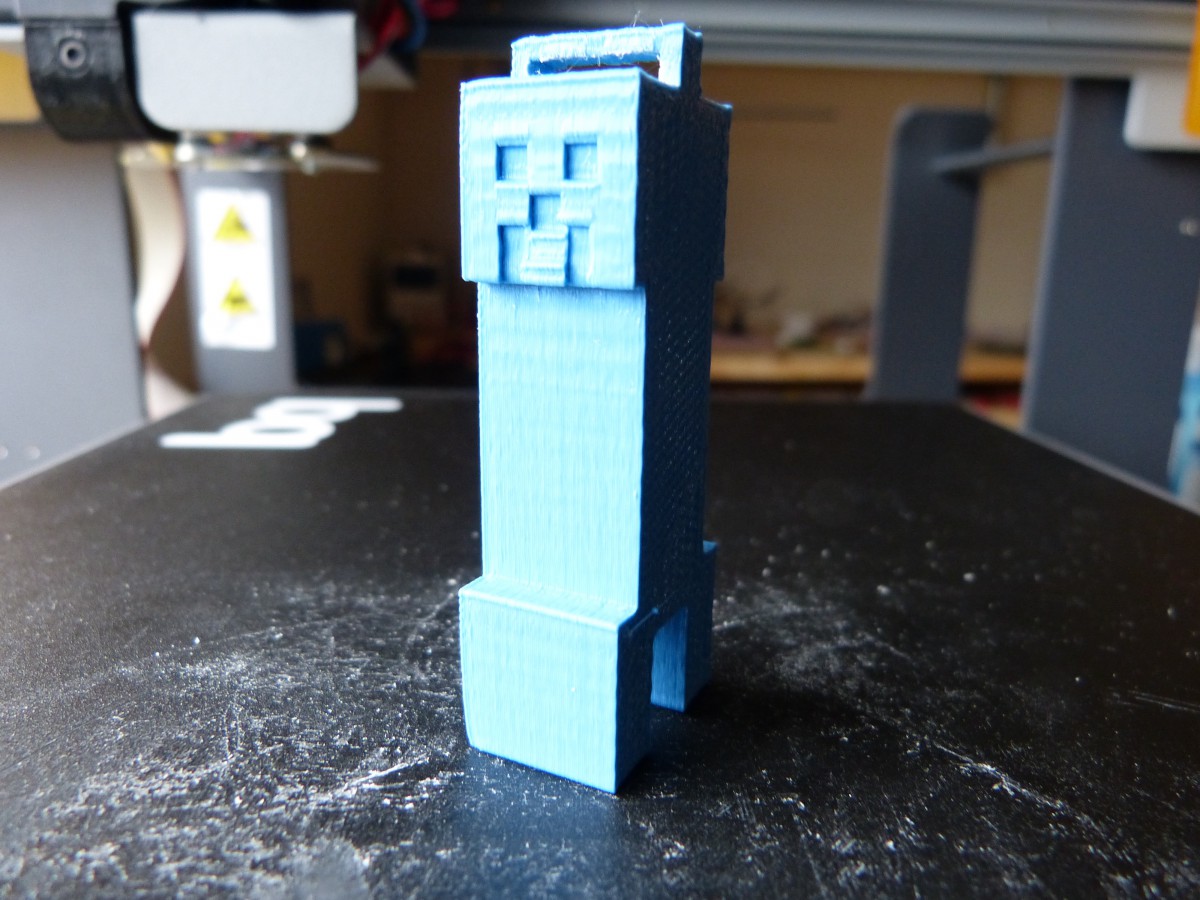

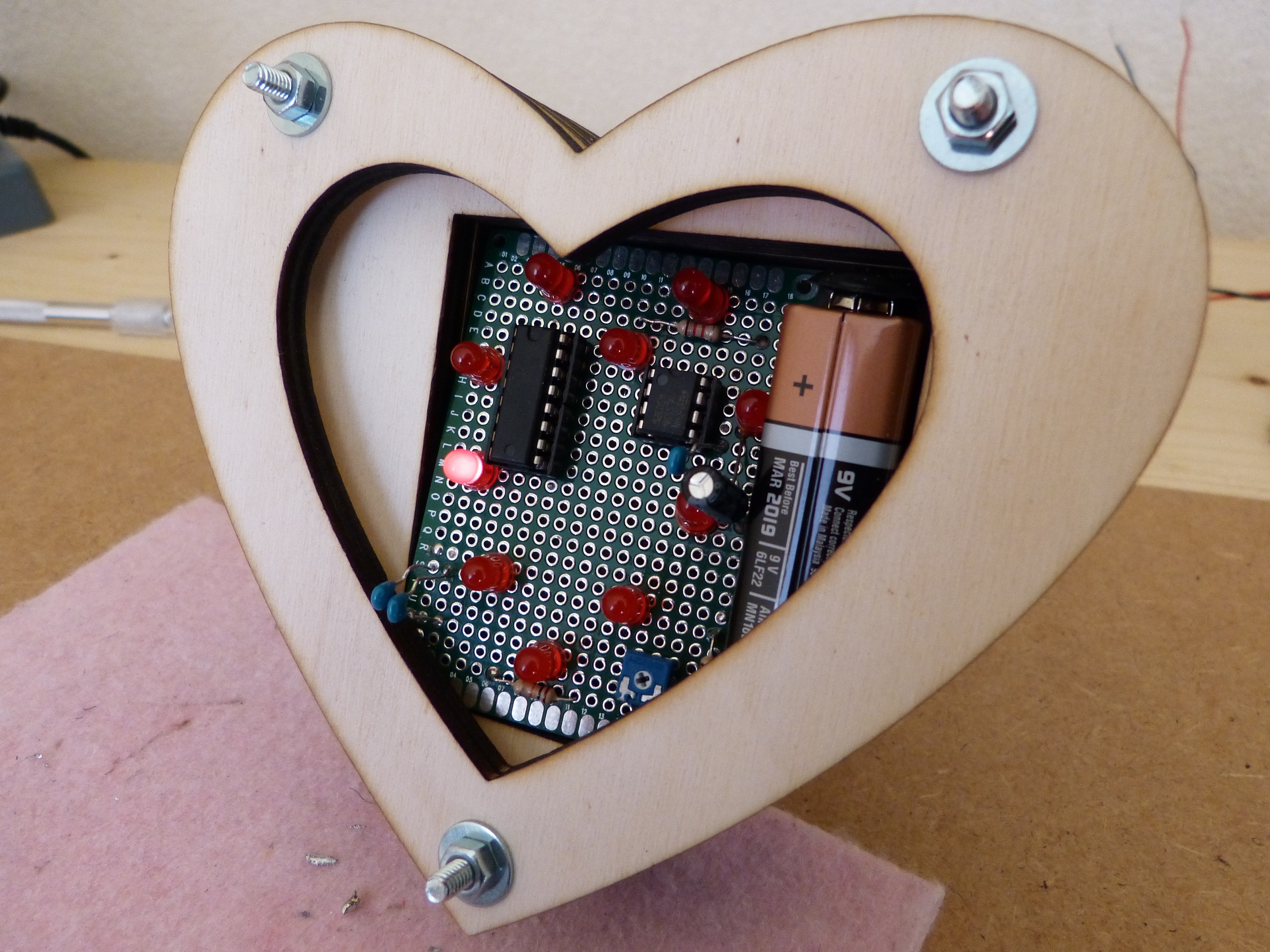

I uploaded my sixth remastered Solvespace video to PeerTube.

My videos remastered on PeerTube

- Post author By Eric Buijs

- Post date February 28, 2020

- No Comments on My videos remastered on PeerTube

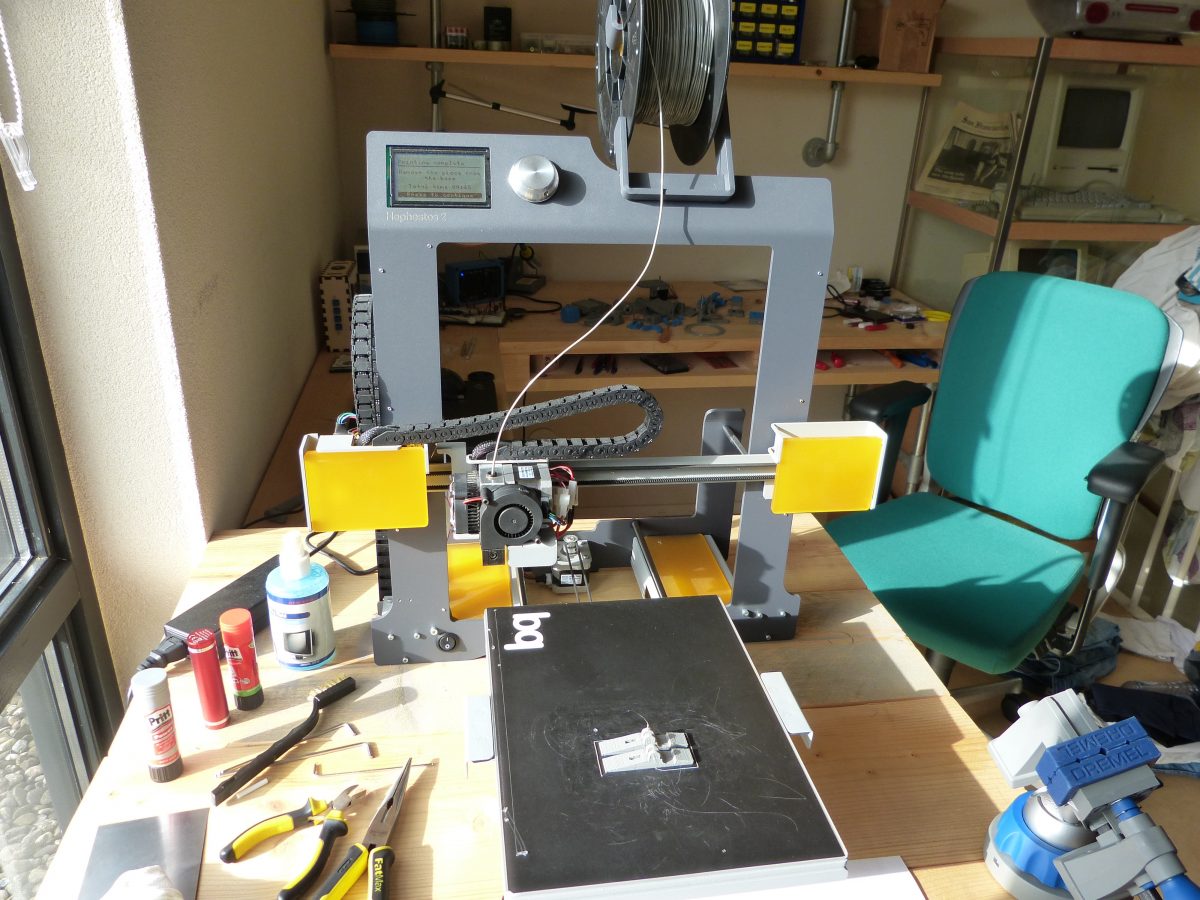

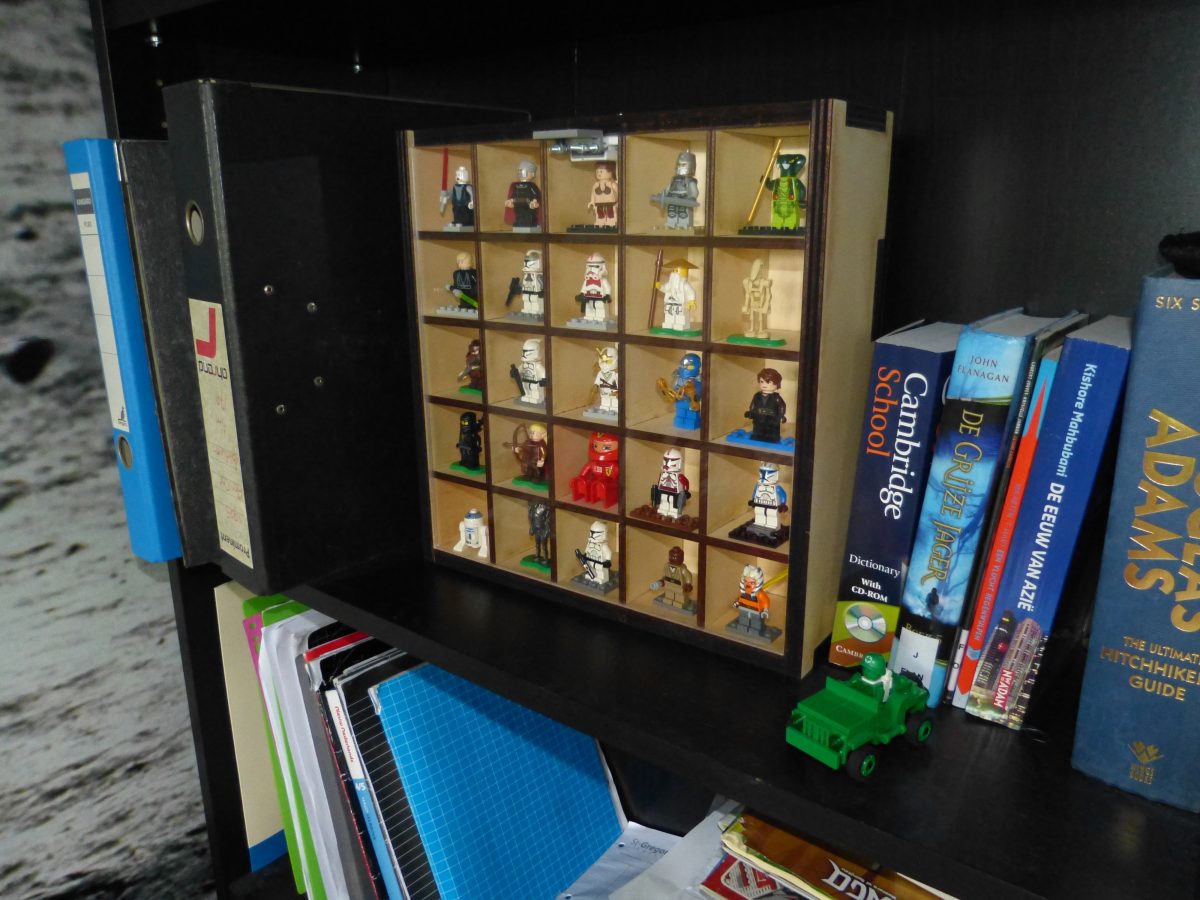

- Tags 3D CAD, 3d modeling, 3d printing, open source, PeerTube, Solvespace