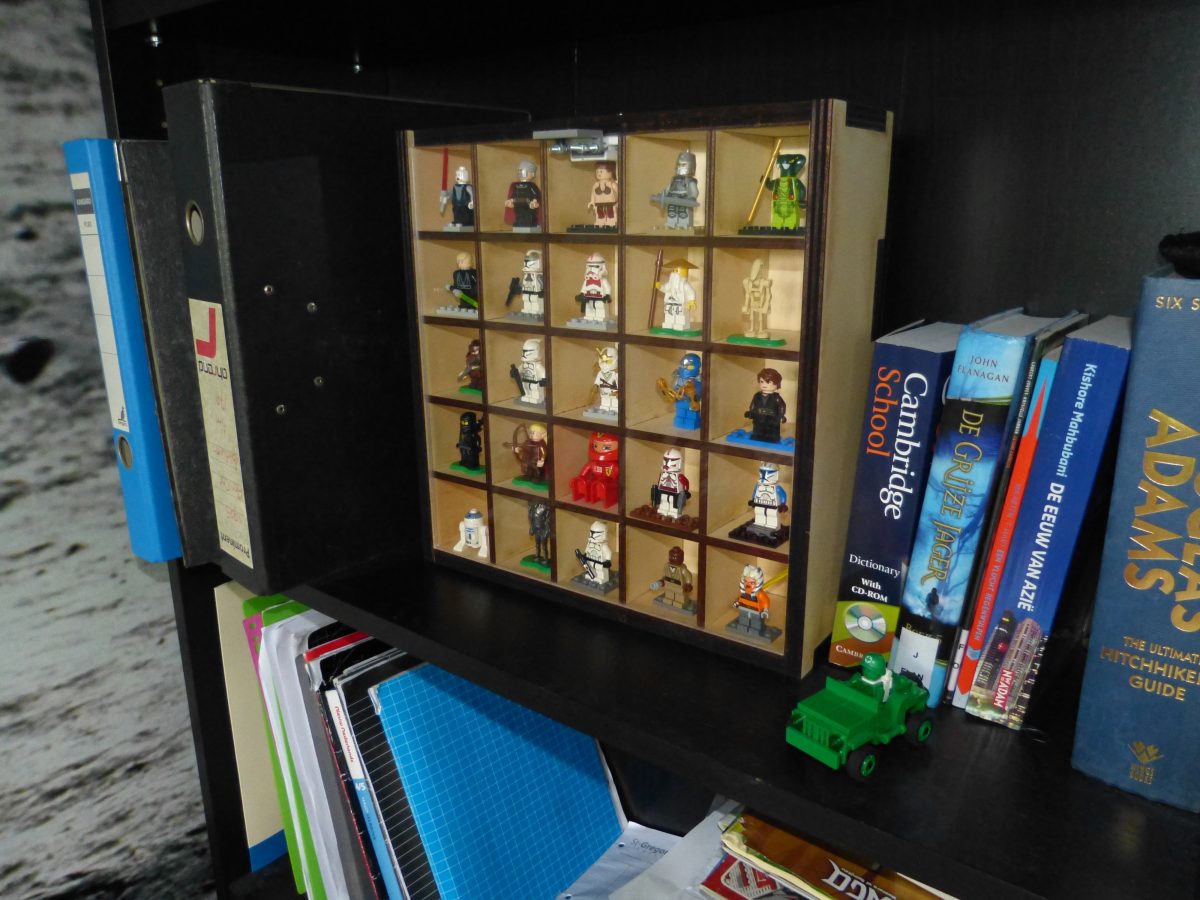

Making a woorden Lego cabinet for all this minifigs is easy and cheap. You do need a laser cutter for this project.

DIY Lego Cabinet

- Post author By Eric Buijs

- Post date November 22, 2016

- No Comments on DIY Lego Cabinet

- Tags 3d modeling, laser cutting, woodworking