Introduction

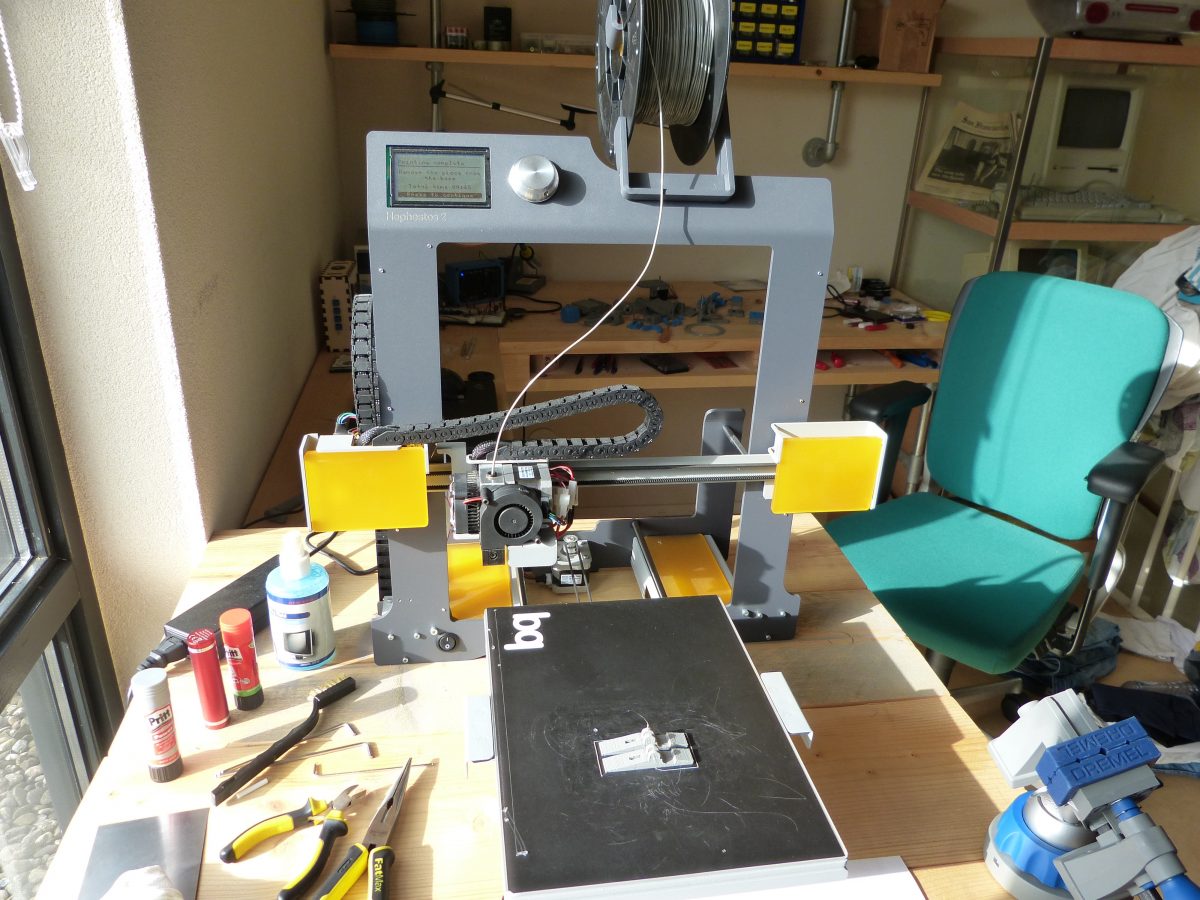

It’s been nine months since I received and assembled my BQ Hephestos 2 printer and I think it’s time to share some of the experiences that I had with it. For those who don’t know the Hephesthos 2 it’s a 3D-printer that is based on the Prusa i3 design with a thick steel frame and almost all metal parts. It’s not cheap but it’s a well designed, high quality 3D-printer with a large printbed. It does have it’s shortcomings but more of that later.

Printing and printing problems

Over these nine months I’ve printed a large variety of objects for different projects mostly without problem. I used both PLA and Filaflex and both materials printed fine. The Hephestos 2 doesn’t come with a heated printbed, one of it’s shortcomings, and I still struggle with the occasional lack of adhesion to the printbed. I ended up using both BuildTak and Pritt and this solves the adhesion problem most of the time however as I found out this is not a guarantee for good results. First of all the printbed must be clean from fingerprints and other contamination. I used to clean the bed rubbing it with warm water on a cloth which is a bad idea because water doesn’t remove oily residue very well. Now I clean the printbed with isopropylalcohol (IPA) making sure that all residue has been removed.

To avoid problems with printing the distance from the nozzle to the printbed is also important. When this distance is too large the first layer becomes messy and adhesion problems occur. I use a piece of paper and place it between the printbed and the nozzle. I consider the distance correct when a piece paper can barely be moved underneath the nozzle.

The z-axis of the Hephestos 2 is not the best possible design. It uses M6 threaded rods (EDIT: actually it’s M5) which can produce an effect called z-wobble. This effect is noticeable in the z direction in my prints from time to time. It would have been better if a z-rod with a higher pitch had been used (such as the Original Prusa i3 Mk2).

Using Filaflex

As mentioned above Filaflex prints fine on the Hephestos 2 but there was a problem with the spool holder. The inner diameter of the Filaflex spool is smaller than the PLA spool therefore it doesn’t fit on the spool holder that came with the printer. When I contacted the supplier about this problem he immediatly designed a spool holder for filaflex which I was able to print and use. An excellent service of the supplier.

Maintenance

The Hephestos 2 as any other 3D-printer does require maintenance. I use oil to grease all the axis from time to time. On top of this I use grease for the threaded rods of the z-axis. I also check the tension on the belts from time to time. The nozzle is cleaned regularly with a brass brush after increasing the temperature to 200 degrees Celcius. The Hephestos came with two long needles that can be used to clean the hotend just by inserting the needle through the nozzle en pushing it all the way through the extruder. Lastly the PTFE tube in the hotend can be replaced with a spare one that came with the printer. Just make sure that the somewhat larger opening of the tube is pointing upwards after it is inserted in the hotend (see also hotends problems below). A maintenance video of the BQ Witbox 2, the enclosed ready to use brother of the Hephestos 2, is available. Unfortunately it is only in Spanish.

It is advisable to check the Allen screws from time to time. Due to the vibration some screws may come loose. Recently one of the threaded rods of the z-axis came loose because of this. Besides a misprint I had to deassemble and realign the z-axis and level the printbed again.

Hotend problems

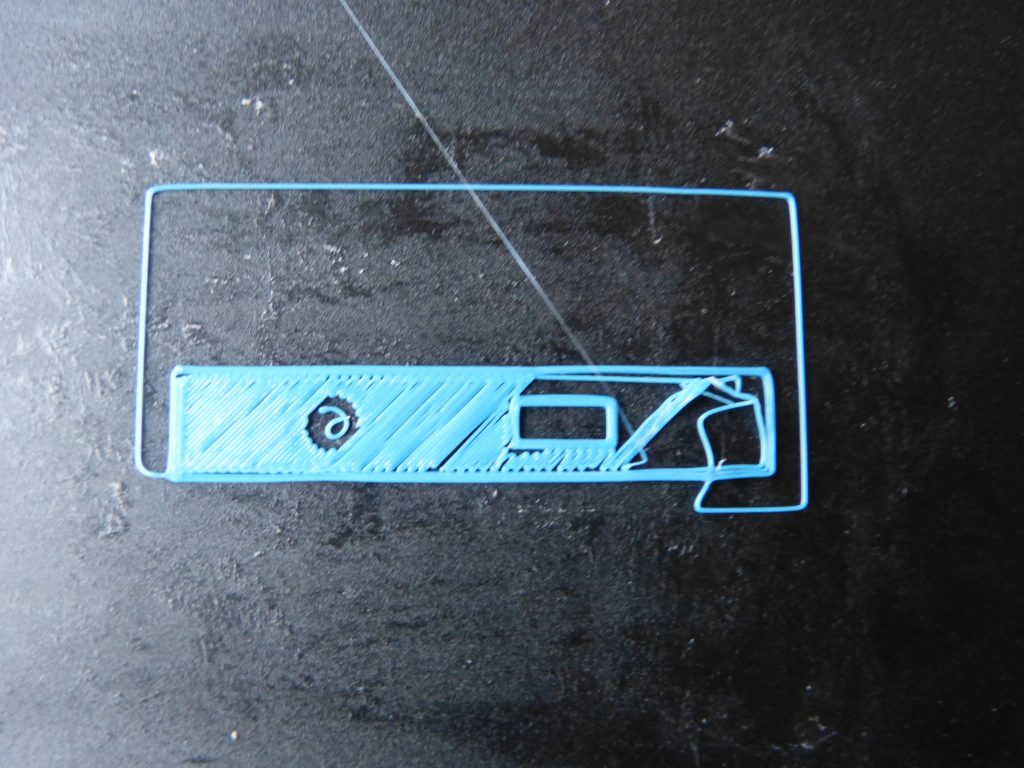

One months ago after changing a filament spool the new filament the extruder made a clicking sound and no filament was extruded from the hotend. The supplier adviced to change the PTFE tube that’s inserted into the hotend. Unfortunately the problem remained but I did notice that a piece of the old PTFE tube was missing. I therefore concluded that pieces of PTFE were stuck in the hotend. I tried to clean the hotend without succes so finally I decided to exchange the hotend with a new one and presto problem solved. The problem was probably caused while changing filament. While removing the filament I pulled it from the extruder which is a bad idea because the PTFE tube can be lifted and damaged in the extruder.

NOTE: Exchanging the PTFE tube is relatively straight forward but make sure that the tube is inserted in such a way that the hotend is positioned correctly in the coldend of the extruder. I damaged my BuildTak layer because the hotend was positioned too low. See the bottom two images for this.

Conclusion

After nine months I can say that I’m still satisfied with the BQ Hephestos 2 printer. I’ve printed numerous models without problems. It doesn’t come with a heated printbed which I believe is a shortcoming. The problems that I had with the printer were mostly solved thanks to the support from the Dutch supplier and the Google+ 3D printing community. As a beginner in 3D printing I can’t stress how important good support is. At some point problems will arise and without support chances are that you can’t solve them and possibly ending a beautiful hobby.

3D printing is a hobby that by nature is very DIY requiring lots of time and the readiness to experiment. This begins with the design of a 3D model in 3D CAD, slicer software to create gcode and working with the 3D printer itself. If you’re willing to do that the BQ Hephestos 2 is a good choice although it’s price can be prohibitive to some.

Thanks for reading!