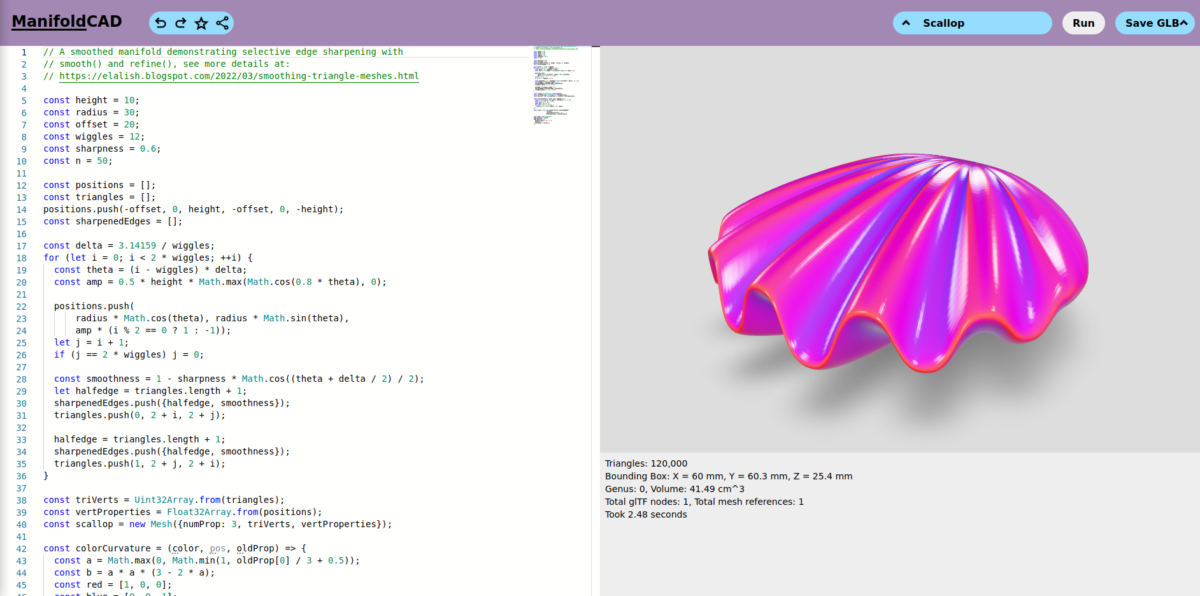

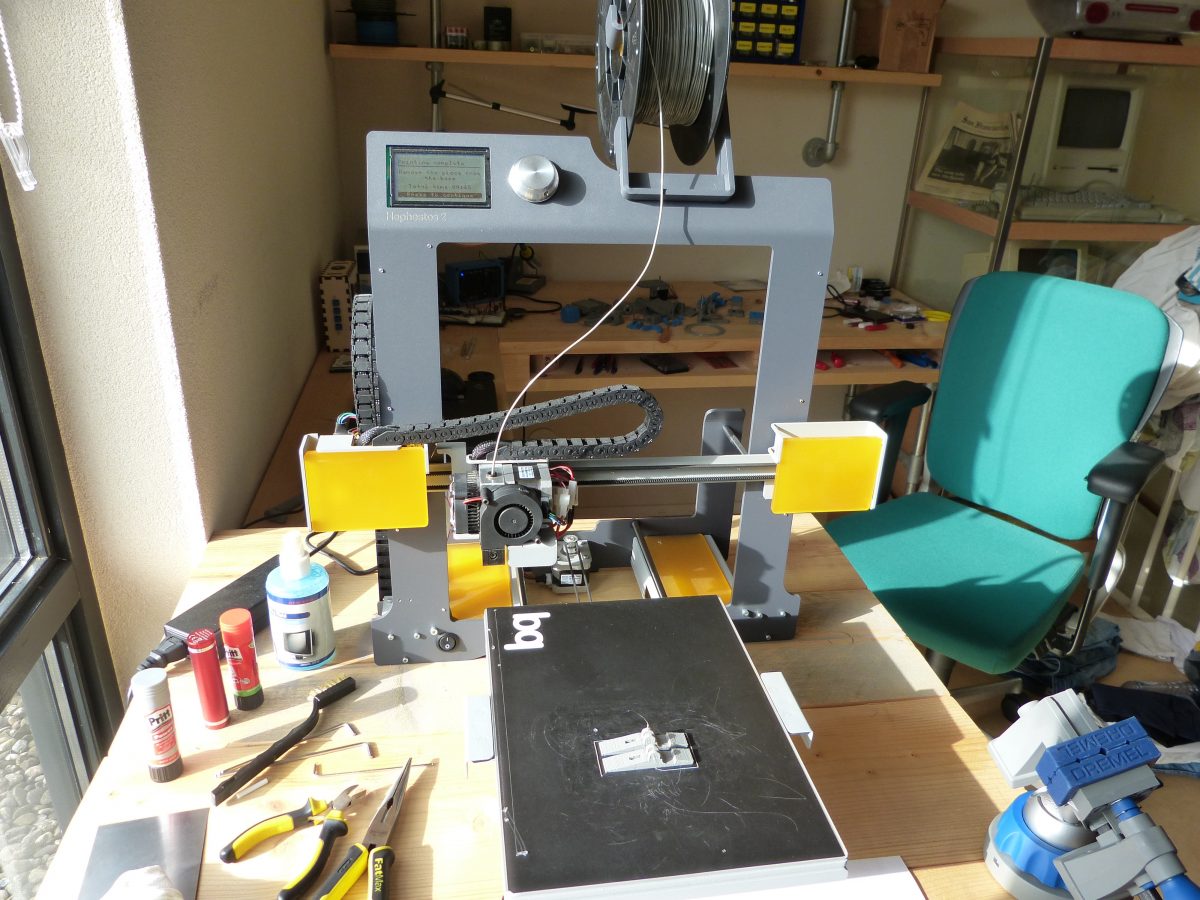

I’ve been taking a brief look at ManifoldCAD, a 3DCAD program in the style of OpenSCAD that runs in the browser and uses Javascript. ManifoldCAD is a relative new project from Emmet Lalish. It’s free and open source software (Apache-2.0 license). In case you are not familiar with these kind of CAD programs, instead of […]