Framasoft published a roadmap for version 3 of Peertube and you can contribute.

DeGoogle my life

According to Wikipedia to DeGoogle is the act of removing Google from your life. As the growing market share of the internet giant creates monopolistic power for the company in digital spaces, increasing numbers of journalists have noted the difficulty to find alternatives to the company’s products. This is my experience to purge my life of Google and I can assure you it’s difficult but if we don’t act soon it will become impossible.

With a lot of people locked into their house most of the time I thought it was a good idea to publish this DIY hangboard for climbers and boulderers. It’s cheap and easy to build.

I uploaded my sixth remastered Solvespace video to PeerTube.

If you’re new to the Fediverse you should know about ActivityPub and why it gives the Fediverse an edge over other social networks.

Welcome to the new decade

In the coming decade we need to take back control of the internet. The Fediverse will help us do that.

YouTube has a monopoly on video and this is bad news. Read what’s so bad about it and why PeerTube is a good alternative.

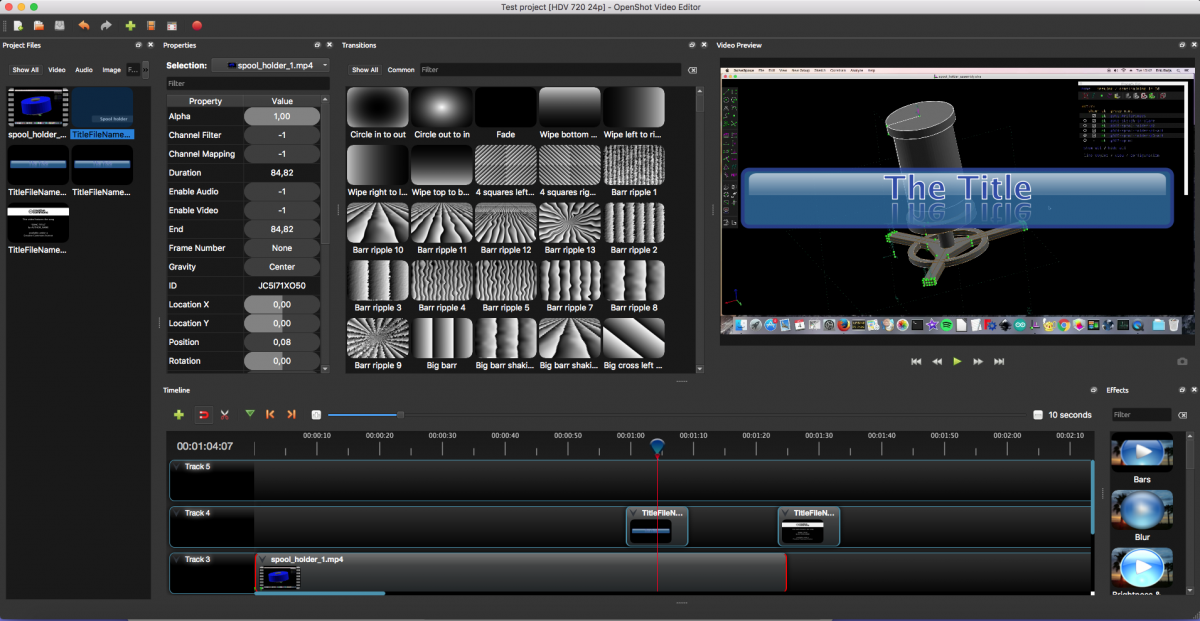

Giving OpenShot another try

After iMovie completely let me down I gave OpenShot another try and it didn’t disappoint.

This article describes how to maintain a Squeezebox server (or Logitech Media Server). All software used for this project is free and open source.

Create your own Squeezebox server (aka Logitech Media Server, aka Slimserver) with a Raspberry Pi and a HDD in six steps.